Foundation Safety Ohio: How to Prevent Slab Settling and Structural Damage

Your foundation is more than just concrete and rebar—it’s the structural core of your home. And in a state like Ohio, where unpredictable weather and unstable soils are the norm, foundation safety isn’t a luxury—it’s a necessity.

Each year, thousands of homeowners across Ohio face issues like cracking slabs, sinking patios, and uneven floors—not realizing these are often early signs of a deeper, dangerous problem: slab settling. Left unaddressed, these issues can lead to structural instability, water infiltration, and even costly foundation failure.

In this guide, we’ll uncover why foundation safety in Ohio is uniquely vulnerable, what causes concrete slabs to shift or sink in this region, and the innovative repair solutions that can protect your property for the long term. Whether you own a home in Columbus, Dublin, or anywhere in Central Ohio, this is what you need to know—before the ground shifts beneath your feet.

1. Why “Foundation Safety Ohio” Matters

Ohio ranks among the states with the most expansive clay subsoils and volatile weather swings. Add more than 56 inches of annual rainfall over 133 wet days and a winter season marked by repeated freeze‑thaw cycles, and you have a recipe for ground movement under nearly every slab in the Buckeye State. US Climate DataGroundworks

2. Understanding Slab Settling

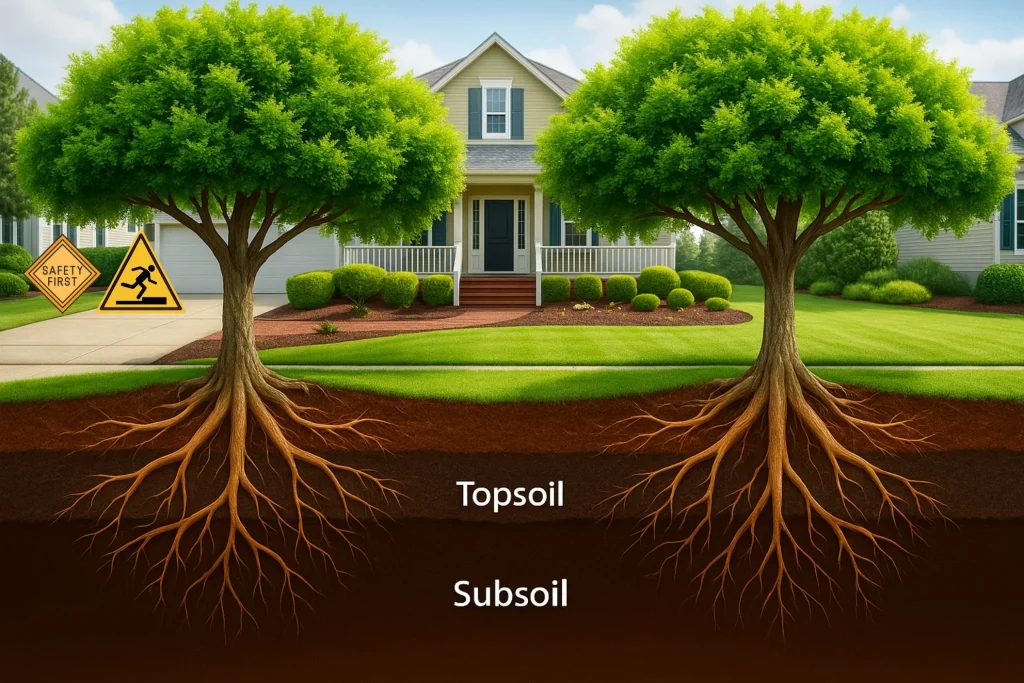

Slab settling occurs when the soil beneath a concrete slab compresses, shrinks, or washes out, allowing the slab to sink unevenly. In Ohio, three forces drive the problem:

| Force | What Happens Underground | Result Above Ground |

|---|---|---|

| Expansive clay | Swells when wet, shrinks when dry | Slab lifts, then sinks, creating cracks |

| Freeze‑thaw cycles | Water in soil expands as ice, then contracts | Repeated heaving and voids under concrete |

| Heavy rainfall & poor drainage | Soil erosion or saturation | Loss of support under slabs |

Local experts note that Columbus-area clays are especially reactive, amplifying seasonal movement. ohiobasementauthority.com

3. Early‑Warning Signs You Can Spot

- Hairline cracks spreading across driveways or basement floors

- Uneven or spongy spots when walking on a patio or garage slab

- Doors and windows that stick—frames go out of square

- Gaps between stair steps, porch slabs, or foundation walls

- Water pooling along the slab edge after storms

Addressing issues at the first sign can slash repair costs by up to 50 percent compared with waiting for wider breaks or vertical displacement.

4. The Hidden Risks of Ignoring Settling

- Trip hazards & injuries—especially dangerous for kids and seniors

- Basement leaks & mold as cracks widen and water finds a path inside

- Framing deformation causing bowed walls or roof misalignment

- Failed home inspections and reduced property value

- Potential legal liability if visitors are hurt on uneven walks

5. How Ohio’s Soil Science Impacts Foundation Safety Ohio

One of the most overlooked factors in foundation safety in Ohio homeowners face is the soil beneath their structures. You might think concrete cracks are a result of age or wear—but often, the culprit is the unpredictable behavior of Ohio’s native soils.

🧪 Clay-Rich Soils and Their Hidden Risks

Much of Ohio is built on silty clay loam, a soil type known for two traits that are especially dangerous to foundations:

- Expansive reaction to moisture – Swells significantly when wet, shrinks when dry

- Low shear strength – Softens easily under heavy rainfall or groundwater saturation

When this happens, the soil loses its ability to support your slab evenly. Uneven pressure causes concrete to crack, dip, or shift—compromising the structural integrity of your home.

💧 Water Table Fluctuations Across Ohio

Areas like Columbus, Grove City, and Gahanna are prone to seasonal water table shifts. Spring rains, snowmelt, and poor drainage cause the water level to rise, saturating the soil. When the water table drops, the dried-out soil shrinks and pulls away from the concrete, leaving behind voids.

These empty pockets beneath your slab are a major contributor to slab settling—a direct threat to foundation safety in Ohio homes.

Maintaining foundation safety in Ohio requires understanding how our region’s unique soils behave beneath your home—not just above it.

6. Professional Solutions: Polyurethane Foam Injection

When voids form or displacement exceeds ¼ inch, it’s time for a precision lift:

| Step | What Happens | Time |

|---|---|---|

| 1. Drill | Technicians core dime‑sized ports in the slab. | 15 min |

| 2. Inject | Expanding polyurethane foam fills voids and gently raises concrete. | 20–40 min |

| 3. Monitor | Laser levels ensure an accurate, uniform lift. | Ongoing |

| 4. Patch & Clean | Holes are plugged with color‑matched mortar. | 15 min |

Why foam beats mudjacking:

- Lightweight—adds almost no soil load

- Hydrophobic—won’t wash out in Ohio’s 56 in. of annual rain US Climate Data

- Fast cure—traffic‑ready in 30 minutes

- Long‑lasting—closed‑cell foam resists decay, rodents, and chemicals

7. Foundation Safety Starts with Top Level Ohio

Top Level Ohio specializes exclusively in polyurethane lifting and foundation stabilization:

- Local soil expertise—we know Columbus clays and freeze‑thaw patterns inside out.

- Licensed & insured—your property is protected every step of the way.

- Free digital inspection reports—complete with elevation maps and photo logs.

- Same‑day repairs—most jobs finish in under three hours.

- Transferable warranty—adds confidence for future resale.

Call 614‑305‑1050 or visit toplevelohio.com to book your free foundation assessment today.

8. FAQs About Foundation Safety in Ohio

Q: How many freeze‑thaw cycles can central Ohio experience in one winter?

A: Some winters see 30 – 40 cycles, each one expanding and contracting soil around the foundation. Groundworks

Q: Does homeowner’s insurance cover slab settling?

A: Generally no, because settling is considered a maintenance issue. That’s why early intervention is vital.

Q: How long does polyurethane repair last?

A: When done by certified pros, lifts routinely last 10–20 years, matching or outlasting replacement slabs.

Q: Will the foam harm my yard or well water?

A: No. Closed‑cell polyurethane is inert, non‑toxic, and NSF‑approved for contact with groundwater.

9. Action Checklist for Ohio Homeowners

| Season | Task | Goal |

|---|---|---|

| Spring | Inspect for winter cracks; clear downspouts | Stop meltwater infiltration |

| Summer | Maintain soil moisture; schedule drainage upgrades | Prevent shrink‑swell gaps |

| Fall | Seal concrete; trim roots near slabs | Block freeze‑thaw entry points |

| Winter | Shovel promptly; monitor interior doors for sticking | Catch early movement |

Keep this chart on your fridge, and you’ll stay one step ahead of slab problems all year.

10. Conclusion: Level Ground, Safer Home

Foundation safety isn’t just about structural engineering—it’s about peace of mind. By understanding Ohio’s unique soil and climate challenges, spotting early signs of slab settling, and acting quickly with Top Level Ohio’s polyurethane injection technology, you’ll protect your family, your investment, and your property’s long‑term value.

Secure your foundation today.

Dial 614‑305‑1050 for a free, no‑obligation inspection or visit toplevelohio.com to book online.