Expert Tips for Basement Waterproofing: Protect Your Home from Water Damage

Expert Tips for Basement Waterproofing: Protect Your Home from Water Damage

Basement waterproofing is a crucial step in maintaining a safe, dry, and structurally sound home. Water intrusion in basements can lead to mold growth, structural damage, and costly repairs. With the right techniques and preventative measures, you can protect your home from water damage. In this blog, we’ll share expert tips for basement waterproofing, ensuring your home stays protected and your basement remains dry.

Why Basement Waterproofing is Essential

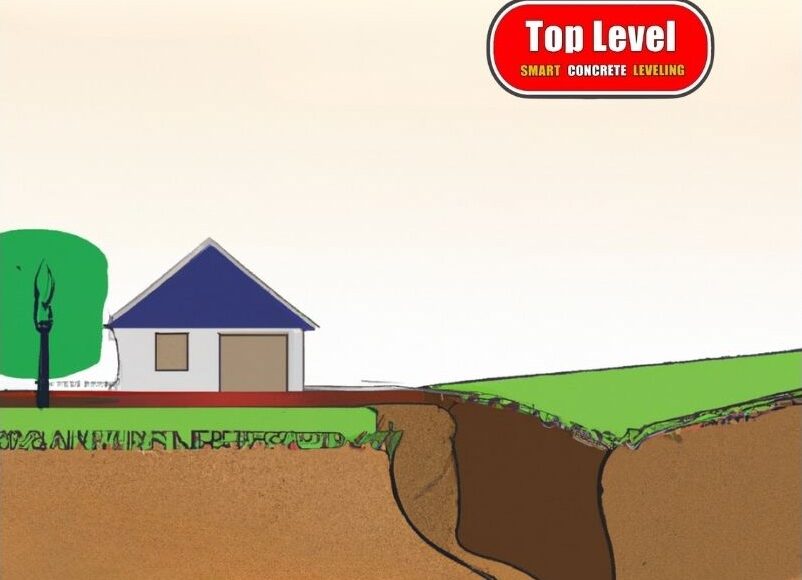

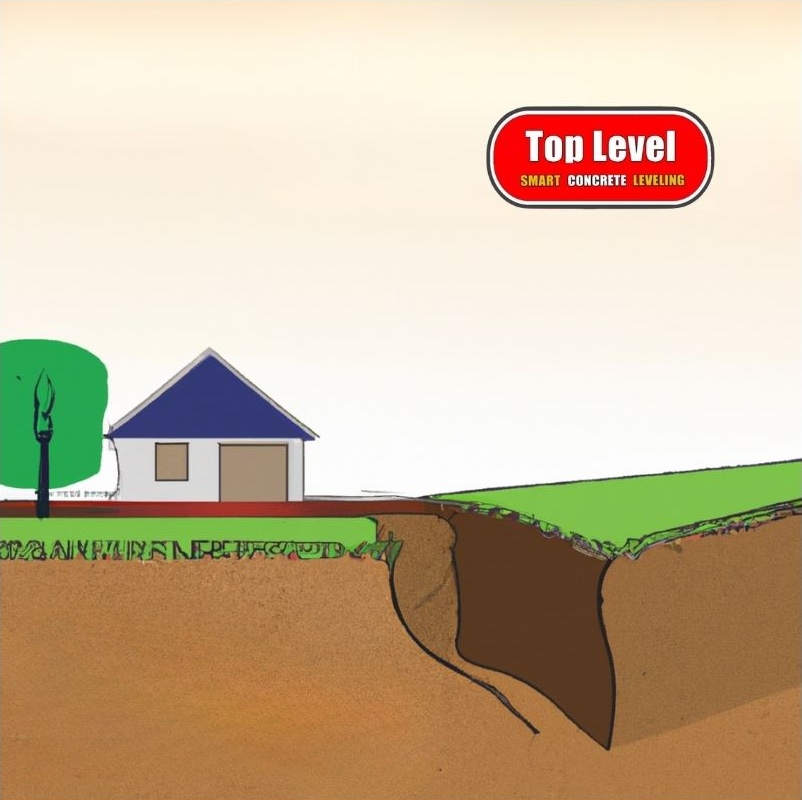

Before diving into our expert tips for basement waterproofing, let’s understand why it’s essential. Basements are naturally prone to moisture because they are built below ground level, where they’re exposed to groundwater pressure. Cracks in the foundation, poor drainage, and improper grading can allow water to enter, causing long-term damage. Waterproofing your basement keeps water out, helping to prevent mold, mildew, and potential health hazards. Moreover, it preserves your home’s value and protects your investment.

1. Identify and Seal Foundation Cracks

One of the primary steps in basement waterproofing is identifying and sealing any cracks in the foundation. Cracks can develop over time due to settling, hydrostatic pressure, or natural soil movement. Water can enter through these cracks, especially during heavy rains. Look for cracks along the walls, floors, and corners of your basement. Use a high-quality epoxy or polyurethane sealant to fill and seal these cracks effectively. This simple step can go a long way in protecting your home from water damage and ensuring a dry basement.

Expert Tip:

Regularly inspect your basement for new cracks, especially after extreme weather events. Early detection allows you to address potential water entry points before they become serious issues.

2. Improve Exterior Drainage with Proper Grading

Improper grading around your home’s foundation can lead to water pooling near the basement walls, increasing the likelihood of leaks. To prevent this, ensure that the ground slopes away from your home by at least six inches over a ten-foot distance. This grading allows rainwater to flow away from your home, reducing water pressure on the basement walls.

Expert Tip:

Consider installing a French drain or a swale to divert water away from your foundation. These drainage solutions are highly effective for areas with heavy rainfall or poor soil drainage.

3. Install and Maintain Gutters and Downspouts

One of the expert tips for basement waterproofing is to keep your gutters and downspouts in good condition. Gutters help collect rainwater from the roof and direct it away from your foundation, preventing water from pooling near the basement walls. Ensure that your downspouts extend at least 6 to 10 feet away from your home to direct water far enough from the foundation.

Expert Tip:

Regularly clean your gutters and downspouts to prevent blockages. Clogged gutters can overflow, causing water to pool near your foundation and potentially leak into your basement.

4. Consider Installing a Sump Pump

A sump pump is a must-have for homeowners who live in areas prone to heavy rain or flooding. This device collects water from the basement floor and pumps it out of your home, keeping the area dry. Installing a sump pump in a sump basin, typically located at the lowest point of your basement, ensures any accumulated water is quickly and efficiently removed.

Expert Tip:

Opt for a sump pump with a battery backup, so it continues to work during power outages. Regularly test your sump pump to ensure it’s functioning properly, especially before rainy seasons.

5. Apply Waterproof Coatings to Basement Walls

Waterproof coatings, such as sealants or paints, create a protective barrier on your basement walls, helping to keep moisture out. These coatings are particularly effective in reducing minor seepage and preventing dampness. Look for waterproof coatings designed specifically for masonry surfaces and apply them to both the walls and floors for added protection.

Expert Tip:

When applying waterproof coatings, ensure the walls are clean and free from any existing mold or mildew. This will help the coating adhere properly and maximize its effectiveness.

6. Improve Interior Ventilation to Reduce Humidity

Basements are often more humid than other parts of the home due to poor ventilation and limited airflow. High humidity levels can lead to condensation, which may encourage mold growth and cause water-related damage. Improve ventilation by installing a dehumidifier to reduce moisture in the air, keeping your basement dry and comfortable.

Expert Tip:

Place the dehumidifier in a central location within the basement, and empty the reservoir regularly. For optimal results, set the humidity level between 30-50% to prevent excess moisture buildup.

7. Install Interior and Exterior Drainage Systems

Interior drainage systems, also known as perimeter drains or French drains, collect water that may seep into your basement and channel it to the sump pump. This type of system works well in tandem with exterior drainage solutions, which direct groundwater away from your foundation. Installing both an interior and exterior drainage system ensures comprehensive basement waterproofing, providing a robust defense against water intrusion.

Expert Tip:

Consult with a basement waterproofing professional to determine the best drainage solution for your specific needs. Proper installation is essential for effective and long-lasting results.

8. Maintain Landscaping Around the Foundation

Your landscaping choices can have a significant impact on your home’s basement waterproofing. Large trees or shrubs with extensive root systems can disrupt the soil around your foundation, causing cracks and enabling water to enter. Opt for plants with shallow roots and place them at a safe distance from your foundation to avoid water pooling issues.

Expert Tip:

Avoid using mulch directly against the foundation, as it can trap moisture and promote mold growth. Instead, opt for gravel or other moisture-resistant ground covers to protect your basement from water damage.

Protect Your Home with Expert Basement Waterproofing Services

Following these expert tips for basement waterproofing can help keep your basement dry and safeguard your home from water damage. Don’t wait until you’re dealing with a flooded basement to take action. Proactive waterproofing not only preserves your home’s value but also protects your family’s health by preventing mold growth and moisture-related issues.

If you’re ready to implement professional basement waterproofing solutions, call us today at 614-305-1050. Our team of experts will assess your home’s unique needs and provide reliable, cost-effective solutions to keep your basement dry and your home safe from water damage.